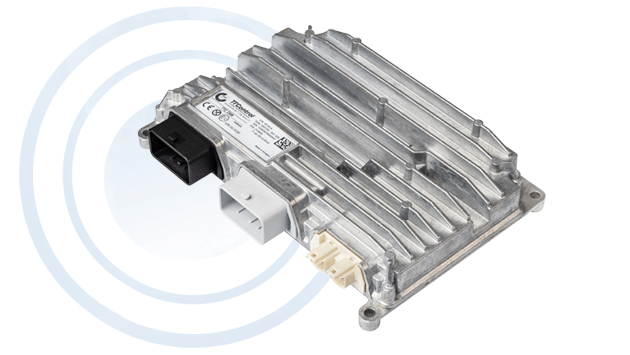

TTC 2300 Family

Powerful and scalable safety electronic control units

for highly automated vehicles

About TTC 2300

The TTC 2300 family is the first member of a complete and scalable series of controllers designed to meet the needs of upcoming highly automated and smart vehicles.

High processing power, high-speed connectivity and large memory make the robust electronic control units (ECU) the ideal choice for advanced electronic architectures and for future automation and assistance systems. The ECUs are designed for use in rugged operating environments and operate under harsh conditions and extreme temperatures.

Product Datasheets

High performance

Innovative features in smart vehicles are leading to an increase of the amount of data to be processed and stored. Therefore, the TTC 2300 family is equipped with large internal and external memory that can be managed by a user-friendly file system. Infineon’s latest high-performance CPU, the second-generation AurixTM TriCoreTM, provides the right computing power, ready for future vehicles.

Flexibility and connectivity for advanced vehicle functions and assistance systems are ensured by an extensive set of inputs and outputs (I/O) and various interfaces like CAN and Ethernet. The highly flexible I/Os make the controllers the perfect, cost-effective solution for a wide range of applications. The inputs can be configured for various sensor types and the outputs can be used to control hydraulic valves, electric motors, lamps or LEDs.

The ECU collects data from analog, digital and smart sensors and can communicate via 100Mbit/s Ethernet fast and efficiently with other components in the vehicle; for example, with a telematics gateway to upload the collected data to the cloud.

Safety-certified by TUeV Nord

The TTC 2300 family variants are safety-certified by TUeV Nord for an extended set of functional safety standards. This increases safety and helps to reduce the overall cost of certifying vehicles.

Software reuse and faster development cycles

The safety-certified, real-time operating system PXROS is part of the software stack delivered with the TTC 2300. It enables full use of the AurixTM multicore architecture. Tasks can be freely distributed to the different CPU cores. The operating system ensures freedom from interference of safety-related and non-safety-related code when executed on the same CPU, which significantly reduces developmental efforts.

The right controllers for electric vehicles

Electrification is a rapidly growing trend that will affect entire industries. The H-Bridge functionality, available in the TTC 2300 product family, efficiently controls various electric motors available for use in vehicles. This not only improves the precision of the vehicle, but also leads to an increasing number of electrified vehicle functions for higher sustainability.

The TTC 2300 family helps introduce innovative, safety-related features, reduces the cost of vehicle testing and validation, and helps the manufacturers stay on the cutting edge of modern vehicle architectures.

Key Benefits

Modularity and software reuse. The TTC 2300 is the first product family of a complete ECU series for smart vehicles. Modular building blocks allow full flexibility to reuse applications across various vehicle sizes and generations

Smart sensors and connectivity. The TTC 2300 family ECUs are not only equipped with an extensive set of inputs and outputs (I/O), but also with various communication interfaces such as CAN, Ethernet and SENT, ready for high-speed connectivity and smart sensors

Future proof. The TTC 2300 variants are future-poof components that enable high-speed connectivity, data processing for intelligent assistance functions, and the ability to control an extensive set of electric motors

Certified components. The TUeV Nord safety certified ECUs help system integrators to reduce the overall cost of vehicle certification

Reduced testing and validation costs. With the TTC 2300 family variants, vehicle manufacturers have the advantage of reduced testing costs and significantly reduced validation effort of the final product

Faster development time. The TTC 2300 variants are an essential component in reducing overall development time. This is due to the real-time operating system PXROS, supporting freedom from interference and the flexible inputs and outputs (I/O)

The TTC 2300 ECUs are equipped with the second generation of the high performance AurixTM TriCoreTM CPU. With up to six cores, each running at 300 MHz, the TTC 2300 family is the right choice for future vehicles. To fulfill the highest security standards, the CPU is equipped with a dedicated Hardware Security Module.

The TTC 2300 family supports advanced data configuration, logging and storing. It comes with up to 6.47 MB internal SRAM and 16 MB internal Flash as well as an external Flash memory of up to 32 MB. In addition, it is also equipped with EEPROM or FRAM memory extensions.

In addition to the Flash option, the controller family supports efficient memory management and data transfer with a user-friendly file system available for all TTC 2300 ECU variants.

The TTC 2300 variants are equipped with up to 60 inputs and outputs (I/O). The I/Os are highly configurable and can be flexibly configured for different types of sensors and actuators, which helps to save time and development costs. Analog and digital timer inputs, both high-side and low-side PWM outputs, as well as PVG control outputs, make the TTC 2300 ECUs the perfect match for a variety of applications.

The controllers are designed for a total load current of up to 45A and high inrush currents.

More automation and assistance systems go hand-in-hand with an increasing number of sensors, and these sensors are getting smarter. The TTC 2300’s modern communication interfaces address the requirements of electronic architectures in tomorrow’s smart vehicles. The TTC 2300 ECU product family has four CAN-FD interfaces with up to two Mbit/s. One CAN channel can be used as wake-up source.

In addition, the control units are equipped with two high-speed data (HSD) connectors for Ethernet and BroadR-Reach communication. These provide the necessary bandwidth for the increasing number of sensor and actuator data in vehicles. Up to four SENT interfaces, including the Short PWM Code (SPC) enhancement, are available.

TUeV Nord safety certified the TTC 2300 family for an extended set of functional safety standards, helping to reduce overall vehicle certification costs: AgPL d for agricultural machinery (ISO 25119); MPL d for earth-moving machinery (ISO 19014); ASIL C for cars, trucks, and buses (ISO 26262); as well as SIL 2 and PL d for machinery (IEC 61508 / EN ISO 13849).

The mixed criticality concept allows both safety-related and non-safety-related code to be executed on the same CPU without reducing the overall safety level (freedom from interference), which helps to significantly reduce time–to-market.

The TTC 2300 product family is delivered with the safety-certified, real-time operating system PXROS. It enables full use of the AurixTM multicore architecture by freely distributing tasks to the different CPU cores. The ECUs can either be programmed in a C/C++ or with CODESYS Safety SIL 2, including support for CANopen Safety Master.

The powerful MATCH toolchain by HYDAC is optionally available and provides enhanced functionality for testing and service in the field.

The TTC 2300 electronic control family answers the rapidly growing industry trend of electrification. For the TTC 2300 family, the possibility of controlling electric motors was considered from the start. The H-Bridge interface supports frequencies up to 1 kHz and currents up to 4A.

Product Overview

| Product | CPU | Number I/Os | Field Bus / Interfaces | Safety Certification / SIL Level | Programming Support |

|---|---|---|---|---|---|

| N4 – Network Controller |

Up to 11970 DMIPS on 4x Arm Cortex- A53 and 3x Arm Cortex-M7 |

2 Outputs 1 Wake-up Input |

1x1000BASE-T1, 6x100BASE-T1, 1x100BASE-TX, 12xCAN (FD), 2xLIN |

ISO 26262 ASIL B |

Yocto GNU/Linux and other POSIX OS possible AUTOSAR Classic envirionment |

| TTC 2310 |

3 cores 32-bit, 300 MHz |

20 inputs (analog, digital, timer, SENT) 36 outputs |

4 x CAN 1 x CAN ISOBUS 1 x CAN (wake-up capable) 1 x LIN |

IEC 61508 SIL 2 EN ISO 13849 PL d ISO 25119 AgPL d SRL2 ISO 26262 ASIL C ISO 19014 MPL d |

C programming (Matlab Simulink I/O Blocklib available) CODESYS® Safety SIL 2 including support for CANopen Safety Master |

| TTC 2380 |

3 cores 32-bit, 300 MHz |

20 inputs (analog, digital, timer, SENT) 40 outputs |

4 x CAN 1 x CAN ISOBUS 1 x CAN (wake-up capable) 2 x Ethernet 1 x LIN |

IEC 61508 SIL 2 EN ISO 13849 PL d ISO 25119 AgPL d SRL2 ISO 26262 ASIL C ISO 19014 MPL d |

C programming (Matlab Simulink I/O Blocklib available) CODESYS® Safety SIL 2 including support for CANopen Safety Master |

| TTC 2385 |

3 cores32-bit, 300 MHz |

20 inputs (analog, digital, timer, SENT) 40 outputs |

4 x CAN 1 x CAN ISOBUS 1 x CAN (wake-up capable) 2 x BroadR-Reach* 1 x LIN |

IEC 61508 SIL 2 EN ISO 13849 PL d ISO 25119 AgPL d SRL2 ISO 26262 ASIL C ISO 19014 MPL d |

C programming (Matlab Simulink I/O Blocklib available) CODESYS® Safety SIL 2 including support for CANopen Safety Master |

| TTC 2390 |

6 cores 32-bit, 300 MHz |

20 inputs (analog, digital, timer, SENT) 40 outputs |

4 x CAN 1 x CAN ISOBUS 1 x CAN (wake-up capable) 2 x BroadR-Reach* 1 x LIN |

IEC 61508 SIL 2 EN ISO 13849 PL d ISO 25119 AgPL d SRL2 ISO 26262 ASIL C ISO 19014 MPL d |

C programming (Matlab Simulink I/O Blocklib available) CODESYS® Safety SIL 2 including support for CANopen Safety Master |

| TTC 590 |

32-bit, 180 MHz |

36 inputs (analog, digital, timer) 60 outputs (36 x PWM with current feedback) |

6 x CAN 1 x CAN ISOBUS 1 x BroadR-Reach® 1 x LIN 1 x RS-232 |

EN 61508 SIL 2 EN ISO 13849 PL d ISO 25119 AgPL d* ISO 26262 ASIL C* |

CODESYS® Safety SIL 2 C programming (Matlab Simulink I/O Blocklib available) SAFERTOS® integration |

| TTC 580 |

32-bit, 180 MHz |

36 inputs (analog, digital, timer) 60 outputs (36 x PWM with current feedback) |

7 x CAN 1 x Ethernet 1 x LIN 1 x RS-232 |

EN 61508 SIL 2 EN ISO 13849 PL d ISO 25119 AgPL d* ISO 26262 ASIL C* |

CODESYS® Safety SIL 2 C programming (Matlab Simulink I/O Blocklib available) SAFERTOS® integration |

| TTC 540 |

32-bit 180 MHz |

52 inputs (analog, digital, timer) 44 outputs (28 x PWM with current feedback) |

4 x CAN |

EN 61508 SIL 2 EN ISO 13849 PL d ISO 25119 AgPL d* ISO 26262 ASIL C* |

CODESYS® Safety SIL 2 C programming (Matlab Simulink I/O Blocklib available) SAFERTOS® integration |

| TTC 510 |

32-bit, 180 MHz |

44 inputs (analog, digital, timer) 40 outputs (16 x PWM with current feedback) |

3 x CAN 1 x LIN |

EN 61508 SIL 2 EN ISO 13849 PL d ISO 25119 AgPL d* ISO 26262 ASIL C* |

CODESYS® Safety SIL 2 C programming (Matlab Simulink I/O Blocklib available) SAFERTOS® integration |

| TTC 508 |

32-bit, 180 MHz |

44 inputs (analog, digital, timer) 32 outputs (10 x PWM with current measurement) |

2 x CAN 1 x CAN ISOBUS 1 x BroadR-Reach® |

EN 61508 SIL 2 EN ISO 13849 PL d ISO 25119 AgPL d* ISO 26262 ASIL C* |

C-programming (Matlab Simulink I/O Blocklib available) |

| TTC 94 |

16/32 bit 80 MHz |

28 inputs (analog & digital) 20 outputs (8 x PWM, 4 PWM with current feedback) |

4 x CAN 1 x LIN 1 x RS 232 |

EN ISO 13849 PL d* |

CODESYS® C-programming (Matlab Simulink I/O Blocklib available) |

| TTC 32S |

16-bit, 80 MHz |

14 inputs (analog & timer) 16 outputs (digital, voltage, PVG and 8x PWM, 6 with current feedback) |

2 x CAN | EN ISO 13849 PL d* | C-programming (Matlab Simulink I/O Blocklib available) |

| TTC 30SH |

16-bit 80 MHz |

14 inputs (analog & timer), 16 outputs (digital, voltage, PVG and 8x PWM, 6 with current feedback) |

1 x CAN | EN ISO 13849 PL c | C-programming (Matlab Simulink I/O Blocklib available) |

| TTConnect 616CS |

3 cores 32 bit 300 MHz |

Not applicable |

6 x 100BASE-T1 BroadR-Reach® 1 x 100BASE-TX Ethernet |

Not applicable |

Not applicable „plug & play“ solution via TTC Downloader |

|

*available for C-programming only |

| Product | CPU | Number I/Os | Field Bus / Interfaces | Safety Certifcation / SIL Level | Programming Support |

|---|---|---|---|---|---|

| TTC 48XS |

16/32 bit, 80 MHz |

28 inputs (analog & digital), 20 outputs (8x PWM) |

1 x CAN | EN ISO 13849 PL d |

Slave software preinstalled – attached to a master controller via CANopen as slave unit |

| TTC 30XSH |

16/32 bit, 80 MHz |

14 inputs (analog & timer), 16 outputs (digital, voltage, PVG and 8 x PWM, 6 with current feedback) |

1 x CAN | EN ISO 13849 PL c |

Slave software preinstalled – attached to a master controller via CANopen Safety as slave unit |

Our web-based service area operated by TTControl contains various program examples, latest documentation, workshop documents, current releases and necessary SW tools to jumpstart development.

This product is supplied by TTControl and distributed for the automotive market by TTTech Auto. For software updates and other technical information, visit the TTControl service area. If you need access, please get in touch with your TTTech Auto sales contact.

Service Area

For further information, including price and availability, please contact products@tttech-auto.com.

Visit the ECU & Displays Service Area