In traditional test drive workflows, identifying and fixing vehicle software issues is often slowed down by repeated debugging loops. Here’s how it typically unfolds:

A test driver encounters a vehicle issue during a drive and reports the problem after completing the route. The recorded debug and vehicle data are submitted to the test data logistics. An expert then attempts to reconstruct the failure based on the provided logs. However, in many cases, the data is incomplete or lacks key diagnostic signals, forcing teams to adjust the measurement configuration and repeat the entire test scenario.

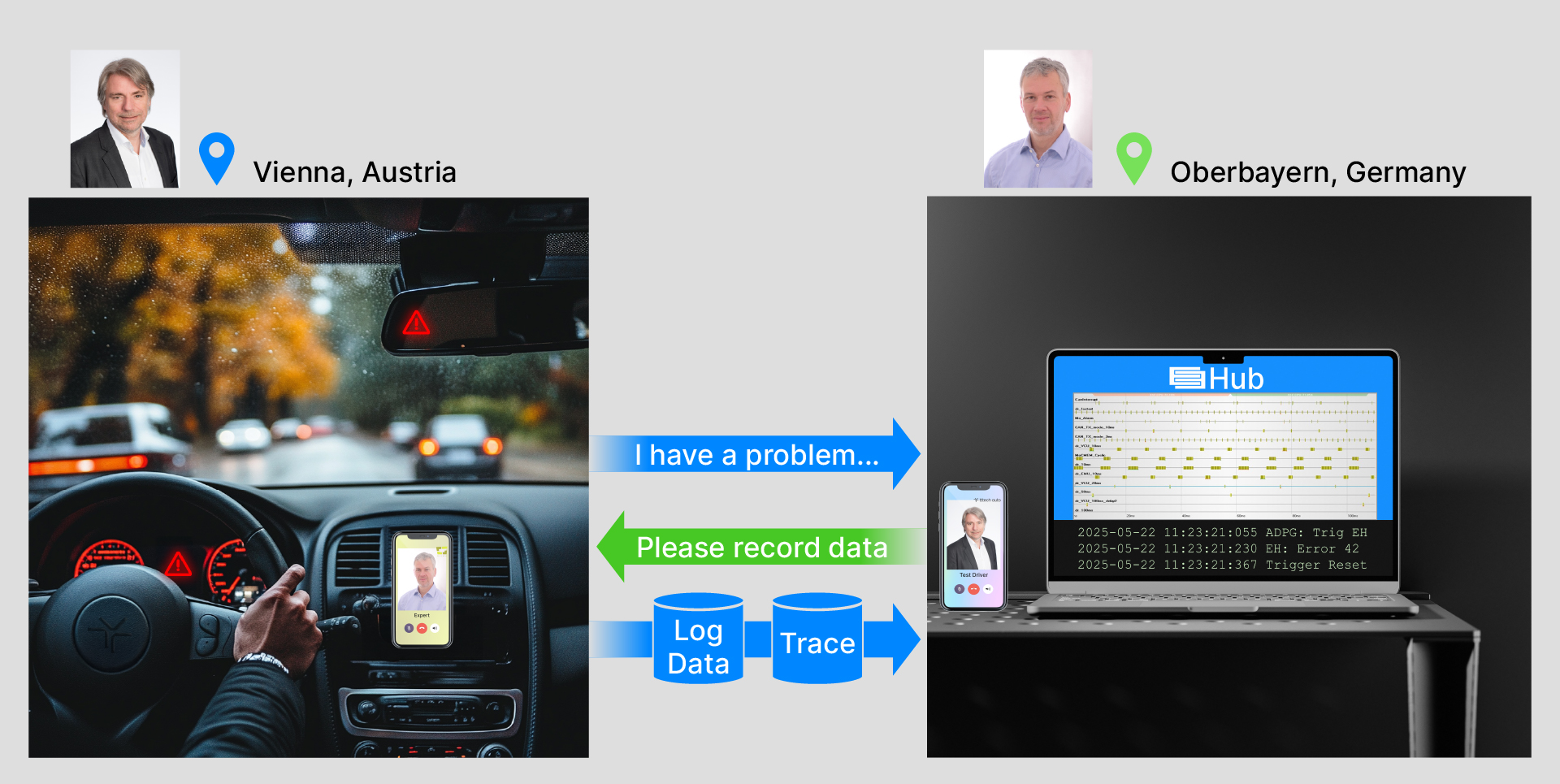

To solve this inefficiency, TTTech Auto, in collaboration with Sleeve and Gliwa, has developed a remote debugging solution that eliminates this back-and-forth.

With a secure live connection to the test vehicle, engineering experts can:

- Access ECU internals in real time

- Adapt measurement configurations on the fly

- Investigate failures without requiring a repeated drive or direct involvement from the test driver

This approach significantly shortens debugging cycles, reduces cost, and increases the effectiveness of vehicle testing.

Discover this cutting-edge solution live at the Automotive Testing Expo in Stuttgart on May 22nd at 11:20 AM, where TTTech Auto’s Kurt Ramsdorf and GLIWA’s Product Manager & Timing Coach, Felix Fastnacht, will present this innovative approach.

Want to dive deeper? Meet our experts at booth 8316 in hall 8 for insightful discussions and hands-on expertise!